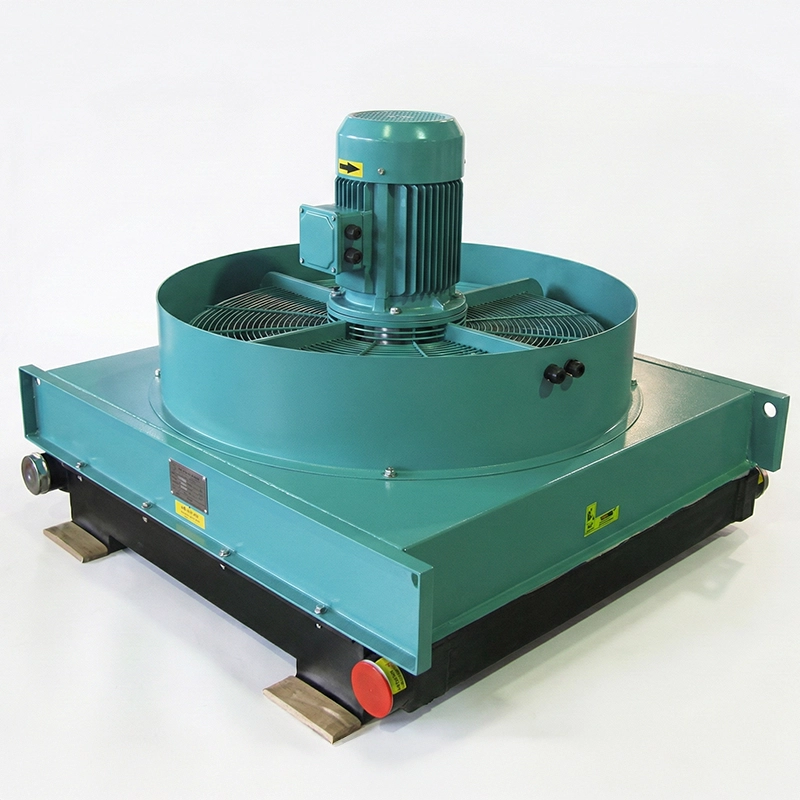

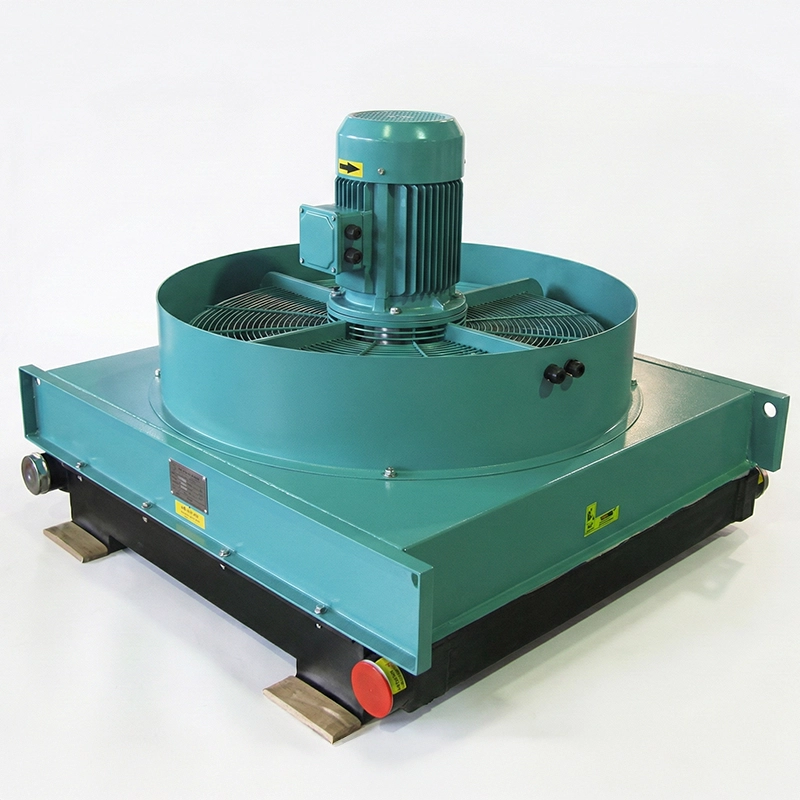

Wind Nacelle Cooling

Additional product images available on request

Need Technical Support?

Our engineers are ready to help you find the right solution.

Contact Engineering TeamSpecialized cooling modules for wind turbine nacelles, managing heat from gearboxes, generators, converters, and hydraulic systems.

Key Features

Overview

XinSheng Wind Nacelle Cooling systems are designed to meet the unique thermal management challenges of wind turbine applications. Our cooling modules provide reliable heat rejection for critical nacelle components while surviving decades of exposure to extreme environmental conditions.

Multi-Circuit Cooling

Modern wind turbines require cooling for multiple systems:

Gearbox Cooling

- High-capacity oil cooling

- Designed for viscosity variations with temperature

- Robust construction for vibration environment

Generator Cooling

- Air-to-air or liquid cooling options

- High-efficiency heat rejection

- Compact installation envelope

Converter Cooling

- Liquid cooling circuits

- Precise temperature control

- High reliability for power electronics

Hydraulic Systems

- Pitch and yaw system cooling

- Brake system thermal management

Design for Reliability

Wind turbine cooling systems must operate reliably for 20+ years:

- Corrosion Resistance - Coatings for offshore and harsh onshore environments

- Fatigue Durability - Designed for continuous cyclic loading

- Serviceability - Accessible for maintenance in nacelle constraints

- Monitoring - Temperature and flow sensors for condition monitoring

Environmental Qualification

Our wind cooling products are validated for:

- Salt spray resistance (offshore applications)

- UV exposure durability

- Wide temperature range (-40°C to +50°C ambient)

- Sand and dust ingress protection

- Lightning strike considerations

Technical Support

We support wind turbine OEMs with:

- Thermal system analysis

- CFD airflow simulation

- Prototype development

- Long-term reliability validation

- Field service support

Technical Specifications

| Core Type | Bar & Plate / Tube & Fin |

| Material | Aluminum Alloys |

| Max Pressure | Up to 30 bar (customizable) |

| Temp Range | -40°C to +200°C |

| Testing | 100% Leak Tested |

Custom specifications available upon request. Contact our engineering team for detailed technical data.

Typical Applications

Click on an application to explore the related industry solution.

Related Products

Genset Radiator Modules

Complete cooling solutions for diesel and gas generator sets, including radiator, fan, fan drive, and enclosure-ready mounting systems.

Modular Cooling Packs

Integrated cooling modules combining radiator, charge air cooler, and oil coolers into optimized, space-efficient assemblies ready for installation.

Battery Cold Plates

Aluminum liquid cold plates for battery thermal management in electric and hybrid vehicles, energy storage systems, and electrified equipment.

Charge Air Coolers (CAC)

High-efficiency aluminum charge air coolers designed for turbo/supercharged engines, reducing intake air temperature to increase power density and fuel efficiency.

Ready to Discuss Your Requirements?

Our engineering team is here to help.